Case Study

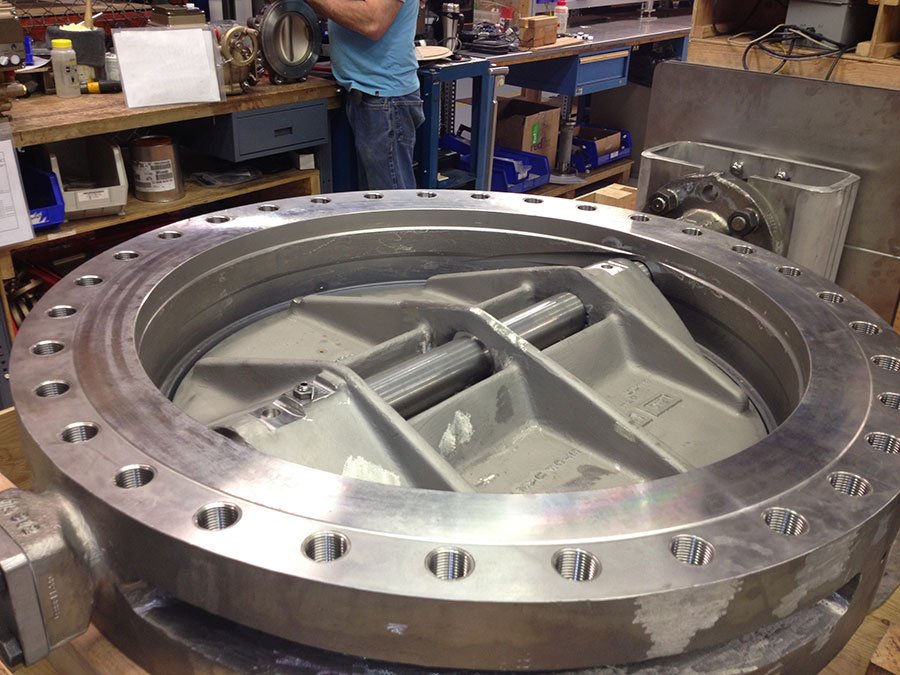

36-Inch-High Temperature Exhaust Valve

Turning an extreme situation into a plug-and-play assembly.

The Challenge:

In 2011, JA Moody was contacted by a US shipyard to provide a solution for an existing engineering problem onboard a newly designed Navy ship. The conditions on the vessel and what needed to be done were extreme. The application was Engine Room exhaust.

JA Moody had to overcome:

- 570C (1058F) design temperature

- Engine back-pressure 30 mBar

- Shock-hardened service (Grade B)

- MOV electric operation with heat shields to protect the motor

The Journey:

JA Moody’s engineering team worked closely with sub-tier contractors Emerson/Vanessa and Curtiss Wright/Nu-Torque to produce a plug-and-play assembly.

The Solution:

Plug-and-play items were produced and delivered, replacing a failed design by a competitor, and placed on the next 17 ships.

Shock Certification:

4130 Ser 501/1716 14 JUL 15

The Result:

No mechanical or functional issues were reported despite these extreme conditions.

To learn more about valve replacement and our rigorous shock and vibe testing, please contact: JA Moody Sales.